TL;DR: Traditional biocide antifouling continuously releases active substances into the water throughout the season—with additional peaks during sanding and washing. In marinas, bays, and lakes, these many sources add up to measurable pollution with clear ecological consequences. By making a smart system choice and using clean maintenance, you can immediately reduce the environmental impact—because every boat counts.

The Environmental Impact of Traditional Antifouling

Traditional antifoulings work by releasing a dose of active substances at the boundary layer with the water. Copper-based antifoulings—the most common product group in Europe—release copper ions, often enhanced by boosters (e.g., copper pyrithione, DCOIT). This happens quietly and steadily. When combined from many hulls, a hotspot effect is created: elevated copper levels in the water and sediment, especially in marinas.

More Copper = Less Diversity

Elevated copper levels trigger a silent process: sensitive microorganisms and sessile algae become rarer, seagrass beds lose vitality, and larvae and juvenile fish have poorer starting conditions. At the same time, increasingly tolerant species begin to dominate—the ecosystem becomes simpler and poorer. Copper stored in the sediment maintains this pressure for years and can be re-released under oxygen or pH stress. It’s the quiet erosion of ecological performance—not just in ports, but everywhere where pollutants accumulate: in bays, lakes, and river estuaries.

How Much Does a Single Boat Really Contribute?

A frequently cited number is "2 kg of copper per pleasure boat (40 feet) per year." The literature shows a range depending on the area, color, and usage profile. A Swiss analysis estimated up to ~1 kg/year for a 9-m boat. For Germany, the Federal Environmental Agency estimates the total load from pleasure boat antifoulings at ~70 tons of copper/year.

The key takeaway is: Every reduction on a single boat lowers the total in the marina. Every boat counts.

Where Biocidal Paints Are Already (Partially) Banned

-

Sweden (KEMI): Biocidal antifoulings are not approved in inland waters and the northern Gulf of Bothnia; on the rest of the east coast, only recipes with less copper are allowed.

-

Germany & Baltic Sea Region: The UBA refers to Scandinavian models (e.g., Sweden) and recommends stricter rules for inland areas; regional restrictions on biocidal paints already exist. Authorities are developing exposure scenarios for inland marinas as a basis for approvals and regulations.

-

Denmark: Stricter requirements for inland areas/fjords, regional product lists, and strict wash water/sanding dust retention in many harbors; in-water cleaning of biocidal paints is generally only allowed with capture and a permit.

-

Netherlands: Rijkswaterstaat/Waterschappen rely on restrictive product approvals in sensitive waters, wash water collection, and IWC bans or mandatory capture for biocidal coatings; biocide-free systems are preferred.

-

Other EU Examples: Several countries/regions have zonal restrictions or stricter regulations for inland marinas (e.g., lower Cu limits, restricted product lists). A common rule: In-water cleaning of biocidal paints is prohibited or only allowed with a capture system.

-

California: The Port of San Diego is on a -76% copper reduction path and promotes biocide-free systems and closed-loop cleaning—a model for European ports that are considering similar programs.

Take-away: The "pioneers" show what's practical and where regulatory authorities in sensitive areas will increasingly move in the future.

If Not Biocides—What Then?

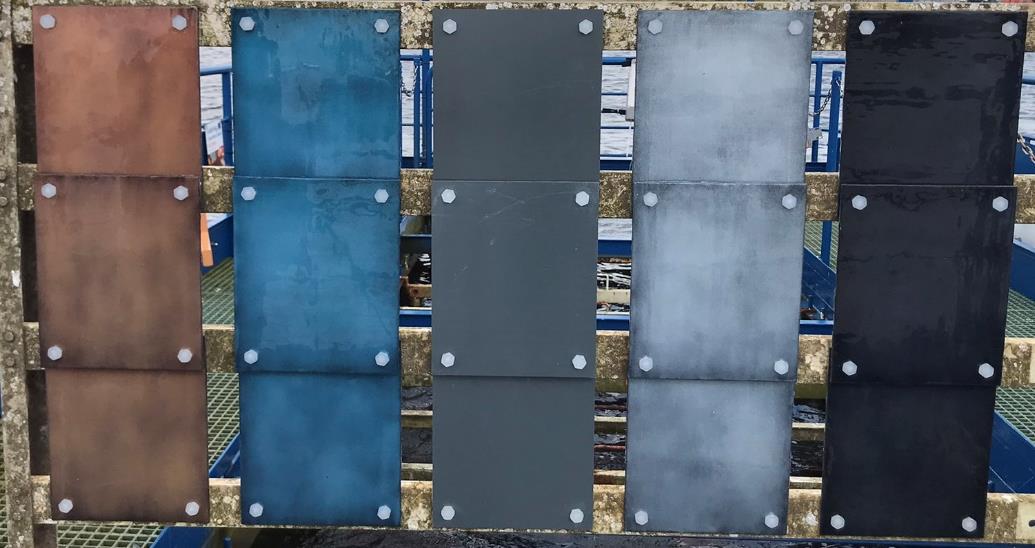

Going biocide-free immediately lowers the chemical load on the water. However, biocide-free ≠ automatically eco-friendly—the material makes all the difference.

-

Silicone-based Fouling-Release: Very low adhesion, good glide effect; growth can be released while sailing or with gentle care. Disadvantage: Risk of abrasion/micro-particle release with hard brush cleaning or mechanical stress; repairs are complex.

-

Fluoropolymers (PTFE/PFAS): Extremely smooth, chemically stable surfaces—but persistence ("forever chemicals") and regulatory pressure. The environmental footprint must be critically evaluated, especially for manufacturing, disposal, and additives.

-

Hard, Smooth Biocide-Free Systems (e.g., F2): Rely on mechanical robustness instead of releasing active substances. A very smooth, durable surface with no abrasion, predictable "gentle clean" maintenance, and long service life. Without copper, without silicones, without fluorinated polymers. This reduces the need for recoats, sanding, and waste.

Conclusion: A Responsibility That Pays Off

The problem isn't one "large single source" of pollution, but thousands of small, continuous sources—and that's exactly where every boat owner has leverage. By choosing robust, biocide-free systems, you immediately reduce the environmental impact and often save time and money in the long run: fewer layers, less sanding, and less waste—leading to more biodiversity in your local boating area.

Sources (Selection)

-

UBA (DE): “Boat hull paints – a problem for our waters” (70 t Cu/year, ~19% of Cu entries) – https://www.umweltbundesamt.de/en/press/pressinformation/boat-hull-paints-a-problem-for-our-waters

-

Chalmers/Water Research: “Antifouling paints leach copper in excess …” – https://www.sciencedirect.com/science/article/pii/S0043135420309180 (Open-Access Manuscript: https://research.chalmers.se/publication/519111/file/519111_Fulltext.pdf)

-

KIT/Environmental Pollution: “Modelling copper emissions from AFP on leisure boats (DE)” – https://www.sciencedirect.com/science/article/pii/S0269749121015438

-

HELCOM Indicator “Copper” (Baltic Sea sediment evaluation) – https://indicators.helcom.fi/indicator/copper/

-

Switzerland/Skippers: “… nine-meter boat up to ~1 kg Cu/year” – https://skippers.ch/de/aktuell/segeln-ozean/gesunde-seen-umweltschonendes-antifouling-86645/

-

ECHA/OECD on PFAS (Persistence/Regulation) – https://echa.europa.eu/hot-topics/perfluoroalkyl-chemicals-pfas · https://one.oecd.org/document/ENV/CBC/MONO(2022)4/en/pdf

-

Microplastics from ship coatings – EU summary/Frontiers – https://ec.europa.eu/newsroom/env/items/718232/ · https://www.frontiersin.org/journals/marine-science/articles/10.3389/fmars.2024.1502000/full

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.