Maximum operating time. Zero biocides.

The future-proof antifouling system for professional fleets.

Project inquiry

More operating time

Extended maintenance intervals, easy interim cleaning.

Cost certainty

Fewer repaint cycles, predictable lifecycle management.

Green Solution

Biocide-free, no leaching of toxic substances into the water.

Versatile in use

Compatible with steel, aluminum, and fiberglass – and even Hypalon/PVC tubes.

The business case for F2 Eco in fleet operations.

In commercial operations, availability, predictable maintenance, and compliance are what matter most.

Conventional biocide-based coatings mean frequent repaints, high maintenance costs, and harmful impact on harbors and inland waters.

F2 Eco takes a different approach:

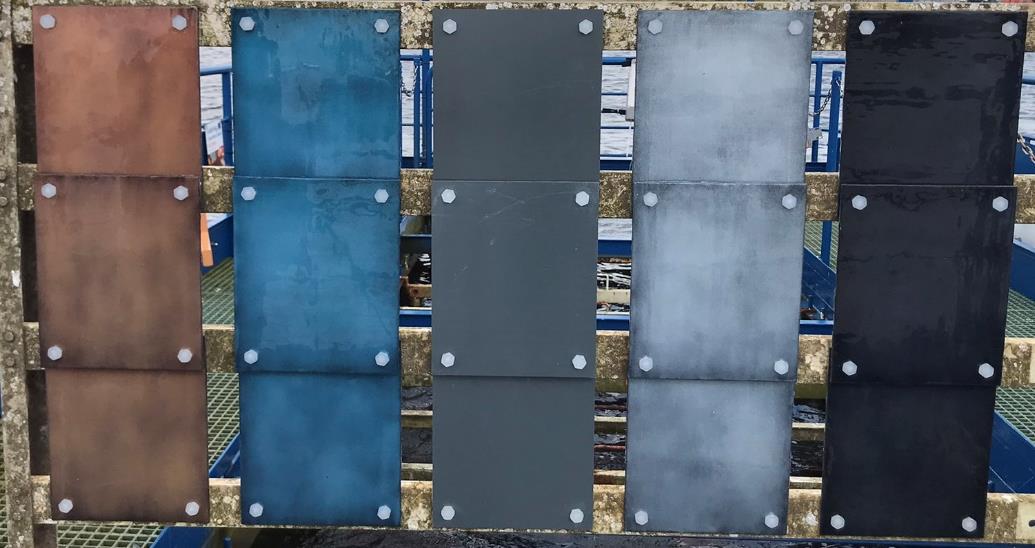

A robust, ultra-smooth, superhydrophobic top coat that makes fouling adhere far less and allows for fast, gentle cleaning. This enables:

✅ longer intervals between yard visits,

✅ quick in-between cleaning without toxic leaching instead of annual repaints, and

✅ a future-proof solution without biocides.

The business case for F2 Eco in fleet operations.

In commercial operations, availability, predictable maintenance, and compliance are what matter most.

Conventional biocide-based coatings mean frequent repaints, high maintenance costs, and harmful impact on harbors and inland waters.

F2 Eco takes a different approach:

A robust, ultra-smooth, superhydrophobic top coat that makes fouling adhere far less and allows for fast, gentle cleaning. This enables:

✅ longer intervals between yard visits,

✅ quick in-between cleaning without toxic leaching instead of annual repaints, and

✅ a future-proof solution without biocides.

Use Cases & Fleet Profiles

F2 pays off wherever schedules are tight, fouling develops quickly, and dock days are costly. Its ultra-smooth, biocide-free surface makes fouling harder to adhere and easy to remove – enabling longer intervals without repainting.

Cargo and container vessels

Large paint surfaces and costly docking windows drive up off-hire and OPEX – especially due to heavy fouling at the waterline and on running gear. With F2, the hull stays smoother for longer; hotspots can be quickly cleaned in-water (with zero toxic leaching). This reduces the repaint scope at the next docking and shortens downtime.

Ferries & shuttles

Tight schedules leave little room for yard time; fouling at the waterline costs both time and fuel. F2 enables quick wipe-downs during turnaround instead of annual full repaints – meaning fewer dock days, longer intervals, and predictable budgets.

Pilot, patrol, government & SAR vessels

Unpredictable call-outs demand maximum availability under strict port regulations. With F2, fouling adheres less and comes off quickly – reducing cleaning effort, biocide-free, and ready for action when it counts.

Cruise ships

Large paint scope, tight turnarounds, and ESG requirements drive up costs. F2 targets critical hotspots first (waterline, running gear) and enables scheduled in-water cleaning (with zero toxic leaching) – reducing paint work at dry-dock, shortening off-hire periods, and ensuring strong ESG compliance.

Fishing & aquaculture

Long lay-ups create heavy waterline fouling and strain tight budgets. With F2, the hull stays smoother for longer, hotspots are quickly cleaned, and paint build-up over the years is reduced – making maintenance windows reliably predictable.

Dredgers, pushers & work fleets

Shallow waters and brackish conditions with heavy fouling pressure, combined with tough operational demands, force frequent repaints. F2 shifts this to predictable intervals with quick in-between cleaning – its robust, repairable layer keeps the fleet available and reduces OPEX.